Basics

Semi’s and other big trucks are large, heavy, complicated machines. They have parts and systems not found on the typical passenger car that must be in safe condition and work properly for the truck to operate safely. Catastrophe can result if they don’t work right. Some of the critical safety parts and/or systems on a truck include:

- Brake systems

- Lighting

- Conspicuity

- Tires and wheels

- Steering and suspensions

- Coupling devices like fifth wheels

Safety equipment problems like steering failure, brake failure or headlight defects and failure or malfunction of other critical safety components can result in fatal truck crashes and catastrophic injury. As an experienced Kansas and Missouri 18 wheeler accident lawyer will tell you typical equipment failures which can lead to a truck crash include:

Brake Failure and Defects

Semi trucks are typically equipped with air brake systems which are more complicated than brake systems on most cars. Typical truck air brake systems utilize an air compressor, air lines, air tanks, brake chambers, protection valves and other parts. These can wear out, break, rust, overheat, become loose or contaminated, go out of adjustment, develop leaks, stop working or develop other problems which affects how well the brakes work. For obvious reasons it is critical that brakes on trucks work properly. In spite of the danger, brake problems including brake failure are among the most common equipment defects found on large trucks.

Brake system problems can reduce brake performance, increase stopping distance or cause complete brake failure. Weight increases the demands on the brake system to the point that the brakes may not be able to stop a truck carrying a load which is more than it’s rated load capacity, Faster speeds also significantly increase the demands on the brake system. Excessive or severe braking use can cause the brakes to overheat resulting in loss of braking force requiring more stopping distance or, in extreme cases, total brake failure with loss of ability to stop the truck. Out of adjustment brakes, worn parts and sudden loss of air pressure in the air brake system can cause braking problems or brake failure. These can increase stopping distance, cause reduced or total loss of control and cause crashes. Faulty brakes can also be a factor in jackknife 18 wheeler accidents. Inspections and preventative maintenance can go a long way to preventing wrecks caused by brake failure.

Some brake defects, when found, are considered serious enough to require that the truck be immediately put “out-of-service” and parked until the problem has been repaired. Some examples are when more than 20% of the service brakes on the truck or combination vehicle are defective, a brake on either wheel of a steering axle that does not work, cracked or broken brake drums, certain problems with the air system and other defects.

Headlight Defects and Other Lighting

Tractor-trailers and other big trucks are large, heavy and can be very dangerous to other vehicles on the road if not seen in time. To reduce the danger, Federal regulations contain very detailed specifications for lighting on 18 wheelers and other commercial motor vehicles including the type of lighting, color, location, placement, quantity and types of vehicles which are required to have the lighting. Specifications include headlights, turn signals, side markers, tail lamps, stop lights, parking lights and others.

Tractor-trailers and other big trucks are large, heavy and can be very dangerous to other vehicles on the road if not seen in time. To reduce the danger, Federal regulations contain very detailed specifications for lighting on 18 wheelers and other commercial motor vehicles including the type of lighting, color, location, placement, quantity and types of vehicles which are required to have the lighting. Specifications include headlights, turn signals, side markers, tail lamps, stop lights, parking lights and others.

Unfortunately, problems with lighting are a common problem. Physical damage, corrosion, vibration, shock, excess or fluctuating voltage and improper grounding can cause truck lights to not work properly. Headlight defects and other problems like other required lights not working properly, insufficient or defective conspicuity devices, turn signals and brake lights not working problems are often found in inspections. Simple steps like not starting the engine with the lights on, using lights with protected with shock mounting, using modern LED lights can all reduce the incidence of light defects.

Conspicuity

Conspicuity is not a frequently used word. It refers to making something clear or conspicuous. It’s very important in the trucking world and to your safety.

Big trucks can be hard to see at night and in other limited visibility situations. This increases the danger to other vehicles of rear-ending the truck or colliding with the side of truck. Rear ending a truck can result in an under-ride collision where the rear of the truck acts much like a guillotine. It can shear off the top of the other vehicle, decapitate the vehicle’s occupants and/or cause other catastrophic of fatal injuries.

In some situations the trucks lights may be not be on, for example if the truck turned off of has experienced electrical problems. Also, depending on conditions and the truck’s position some or all of the lights may not be easily seen or recognized in time for the driver of another vehicle to react in time. Accordingly, these trucks are also required to have reflectorized or “conspicuity” tape in certain areas like the side and rear.

Tire or Wheel Problems

Heavy truck tires are larger, heavier and constructed differently that typical passenger car tires. Federal regulations contain detailed specifications for tires including condition, tread depth, permissible load and inflation pressure. Wheels and rims may not be broken, cracked, out of round bolt holes and wheel lugs or nuts must be present and not loose.

The portion of large truck tires in contact with the road is often built thicker so as to allow the tires to be “regrooved”. This is a process where new tread grooves are cut into the into a tire where the original tread has worn down. There detailed rules on when these regrooved tires may be used as well as rules on retread and recapped tires.

Tire defects like insufficient tread depth and flat or leaking tires are not unusual. Worn or damaged tires may experience a blowout causing a potentially catastrophic loss of control. Improper tire inflation, not inspecting tire condition or not replacing damaged or worn tires are known to be associated with tire failure. Regular inspections to identify worn, damaged or deteriorated tires, ensuring that tires are properly inflated and that wheel nuts are properly tightened are important measures to prevent big truck accidents in Missouri, Kansas and across the United States caused by tire or wheel problems.

Steering Failure

The steering system is one of the truck’s basic control mechanisms. The steering system can deteriorate slowly over time or fail suddenly and with potentially catastrophic results. Not properly greasing steering joints, replacing worn out parts and not checking power steering fluid levels are known contributors to steering failure.

Federal Motor Carrier Safety Regulations

The Federal Motor Carrier Safety Regulations (FMCSRS) contain very detailed requirements for safety equipment on trucks. Parts like lights, brakes, tires, exhaust systems, fuel systems, mirrors, glass, heaters, windshield wipers and washers, heaters, couplers and emergency equipment are all addressed. As an example, there are twelve separate regulations, most of which have multiple subparts, just on the subject of truck lights with extremely detailed requirements for lights and reflectors, including their quantity, color, location and how far above road height they must be mounted. There are pages of diagrams showing the proper position for lighting on different types of trucks. It gets that detailed. Because the FMCSRS can be so critical, it is important that your trucking accident law firm be familiar with and know how to use the FMCSRS in your case.

Inspections

To reduce big truck wrecks caused by equipment failure, the FMCSRS include comprehensive requirements for truck inspections. At the end of each workday drivers are required to inspect the truck and usually prepare a driver vehicle inspection report (DVIR) covering the condition of the truck’s brakes, steering, tires, lights and many other parts. Before driving the truck again, drivers are required to review the previous DVIR, make sure that all defects noted on it have been repaired and also confirm that certain parts of the truck are in good working condition. The FMCSRS also require annual inspections.

To reduce big truck wrecks caused by equipment failure, the FMCSRS include comprehensive requirements for truck inspections. At the end of each workday drivers are required to inspect the truck and usually prepare a driver vehicle inspection report (DVIR) covering the condition of the truck’s brakes, steering, tires, lights and many other parts. Before driving the truck again, drivers are required to review the previous DVIR, make sure that all defects noted on it have been repaired and also confirm that certain parts of the truck are in good working condition. The FMCSRS also require annual inspections.

Motor carrier inspectors and law enforcement also conduct roadside inspections. If certain problems are found, the truck can be taken “out of service”. This means that the truck may not be driven again until the problem causing the truck to be taken out of service is fixed. If a truck is taken out of service, in some situations it may have to be towed to the repair facility rather than driven there.

Injury Potential

Heavy trucks should not be on the road with worn-out or defective component systems and parts. Equipment failure on a massive commercial truck can cause its driver to lose control of the vehicle and possibly lead to extensive injuries, damage, and even death. Proper inspection and maintenance can go a long way to reducing catastrophic injuries resulting from equipment failure.

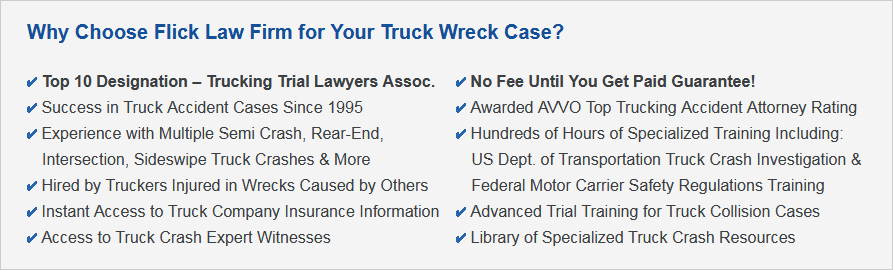

If you or someone you love is seriously injured, disabled, or killed in a truck accident caused by equipment failure or malfunction, call Flick Law Firm at (816) 221-0501 right away. We can investigate your claim and help you obtain fair compensation for your accident-related damages, including medical bills, reduced earning capacity, lost wages, property damage, and pain and suffering.

LAWRENCE FLICK LAST REVIEWED AND EDITED THIS PAGE ON MAY 18, 2020